Our Company History

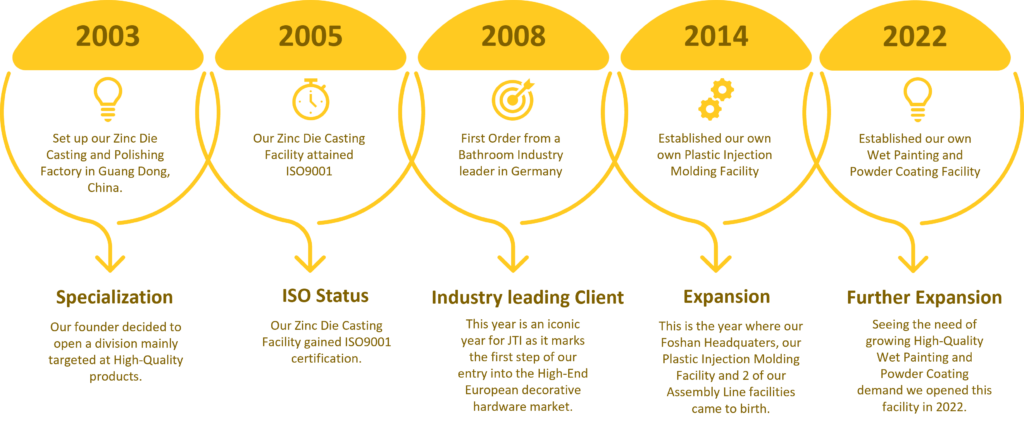

In 2003, after setting up our first Zinc Alloy Die Casting and Polishing facility specialized in High-Quality we attained our first ISO9001 certificate for that facility. In the years that followed, our orders from other bathroom industry leaders in Europe grew, and our clients, very satisfied with our service required more diverse products. Therefore, in 2014 we opened our Foshan headquarters, our own Plastic Extrusion Factory and 2 more Assembly Line facilities to cater for the growing demand. The name JTI comes from our parent company Juntong Industries Limited which is registered in Hong Kong. It is wholly owned by Ritz and an entity in which is used for sales and investment to improve on our production facilities.

In 2015, with our increasing orders for High-Quality Zinc Alloy Die Casted products and Plastic Extrusion products we were able to take up a specialized electroplating line with one of our major electroplating partners. This greatly improved our technical expertise with our chrome plated parts and PVD parts and also helped us achieve even more competitive pricing for our customers. Furthermore, in 2015, we also partnered intensively with our Aluminum Extrusion and Anodizing Partner, combined with our technical know how and expertise, we were able to grow our partner into developing aluminum products suitable for High End European Customers in the bathroom industry. This great collaboration proved vital as it helped us develop aluminum products for clients that require aluminum profiles for complete sets of shower enclosures.

During The Years...

Our business continued to grow organically and we had successful collaboration with more clients. Furthermore, in the year 2015, our product range grew and we catered for more High-Quality bathroom industry products. During this year, we shared our technical expertise and extensively helped grow one of our present stainless steel and brass partners. Until this day, this type of investment proved successful as we are able to consistently provide High-Quality stainless steel products for bathroom and kitchen accessories as well. In 2020 we started seeing a growing trend for more products that required wet painting and powder coating surface requirements. Therefore, in 2022 we invested in our own Wet Painting and Powder Coating Facility. We poured a lot of technical expertise and efforts into this facility and we believe it has helped us gain a further competitive edge as we believe the surface quality of our products and the pricing competitiveness that we now provide are unrivaled in the Guang Dong region.

Lastly, as our customer base of High-Quality clients grew, we managed to attain a unique Economies of Scale. Usually, the demand for high quality products is not as high as lower quality products, so a single client in need of High-Quality products with a single range of product might not be able to benefit from economies of scale. Initially, we experienced this problem. However, as our base of clients requiring High-Quality products grew, we were able to gather the orders together and benefit from economies of scale. This produced a compounding effect and benefitted our clients even more as we were able to offer even more competitive prices.